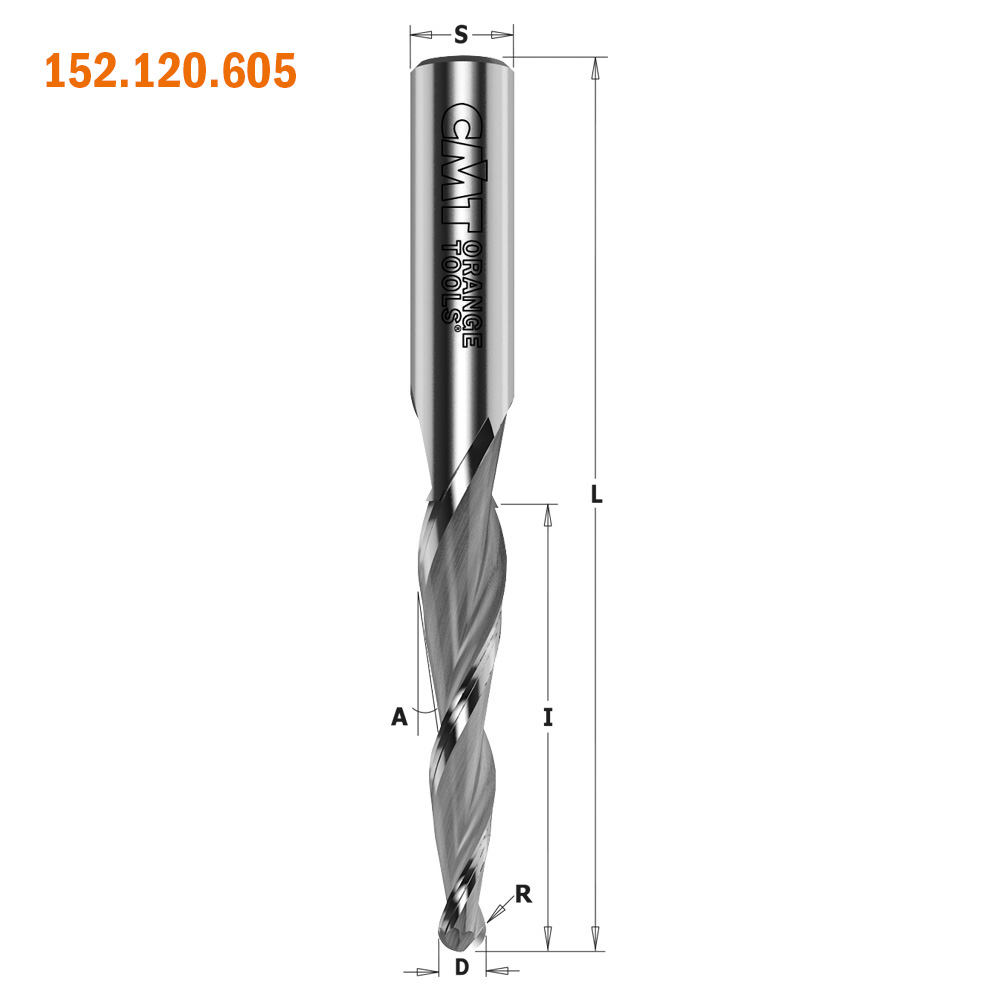

Solid Carbide Upcut 2D/3D Carving Tapered Ball Nose Spiral Bits

152

Technical details:

• Premium quality HWM.

• Upcut spiral cutting edges [Z2/Z3].

• Excellent finish on the lower side of the work piece.

• Upward chip ejection.

Application:

specially designed for 2D and 3D CNC profiling and carving in plastic, aluminum & wood for several uses like:

• A perfect bit for 3D carving

• Precision 2D and 3D large scale carving

• Great for deep profiling

• Dimensional signage

• 3D millwork

• 2D and 3D contouring, profiling, modeling and pattern making for cabinetry, sign making, furniture making and jewelry mold making

• Perfect for model-makers on large 3D milling profiles in abrasive EPS foam and other materials.

• Ideal on aluminum, plastic and wood-based materials.

Excellent for cutting:

• Acrylonitrile-Butadiene-Styrene (ABS)

• Acrylic

• Acrylic Stone

• Aluminum

• Brass

• Bronze

• Composite

• Copper

• CORIAN®

• COROPLAST®

• DIBOND®

• ETHAFOAM®

• Ethylene-vinyl Acetate Foam (EVA)

• Expanded Polypropylene (EPP)

• Expanded Polystyrene Foam (EPS)

• Extruded Polystyrene Foam (XPS)

• Fiberglass

• Fiberglass PCB Board

• Foam Board

• Graphite

• HDPE

• HDU

• 20lbs High Density Urethane

• LEXAN®

• MDF/HDF

• PALFOAM™

• Phenolics

• Phenolic Composites

• Plastics

• Poly (methyl methacrylate) (PMMA)

• Polyethylene Foam

• POLYLAM®

• Polyurethane Foam

• PVC

• PVC Foam Board

• Sign Board

• Sign Foam

• Titanium

• Tooling Board

• Wood

• XPE (Cross Linked Polyethylene) Foam

Tips for Milling Plastics:

• pay attention to heat input.

• pay attention to chip-loads when using small diameters.

• use air-blast to keep chip away and cooling the tool.

| Item Code | D | R | A | I | L | S | Z | MAT | RH-LH |

|---|---|---|---|---|---|---|---|---|---|

|

152.060.082

|

0.8 | 0.4 | 5.5 | 25 | 70 | 6 | 3 | HWM | RH |

|

152.064.082

|

0.8 | 0.4 | 6.2 | 25.4 | 76.2 | 6.35 | 3 | HWM | RH |

|

152.064.162

|

1.6 | 0.8 | 5.4 | 25.4 | 76.2 | 6.35 | 3 | HWM | RH |

|

152.060.162

|

1.6 | 0.8 | 4.5 | 25 | 70 | 6 | 3 | HWM | RH |

|

152.080.163

|

1.6 | 0.8 | 5.5 | 30 | 80 | 8 | 3 | HWM | RH |

|

152.120.208

|

2 | 1 | 3 | 80 | 120 | 12 | 2 | HWM | RH |

|

152.080.325

|

3.2 | 1.6 | 2.5 | 50 | 90 | 8 | 3 | HWM | RH |

|

152.060.323

|

3.2 | 1.6 | 2.5 | 30 | 70 | 6 | 3 | HWM | RH |

|

152.064.322

|

3.2 | 1.6 | 3.6 | 25.4 | 76.2 | 6.35 | 3 | HWM | RH |

|

152.120.605

|

6 | 3 | 3 | 50 | 100 | 12 | 2 | HWM | RH |

|

152.127.635

|

6.35 | 3.2 | 3 | 50.8 | 101.6 | 12.7 | 2 | HWM | RH |