Select Language

Language

Select Market

Select

Login

Login to enter your Member Area

Search item

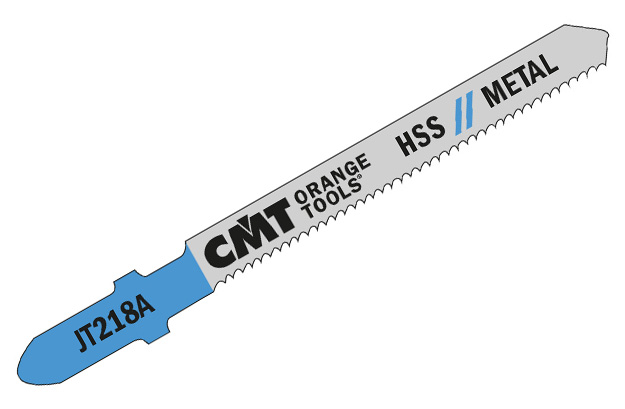

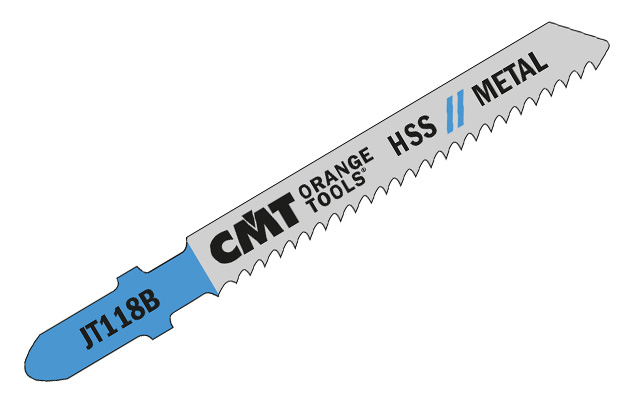

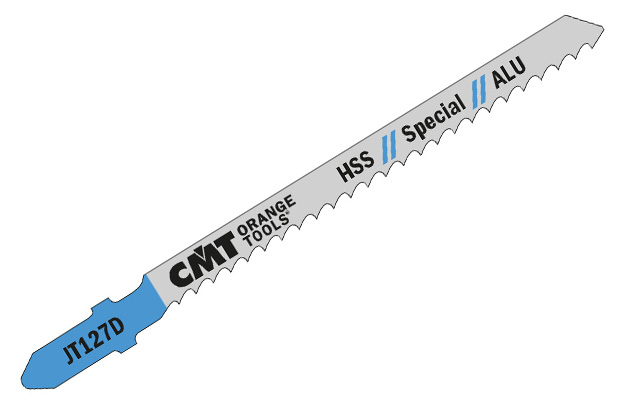

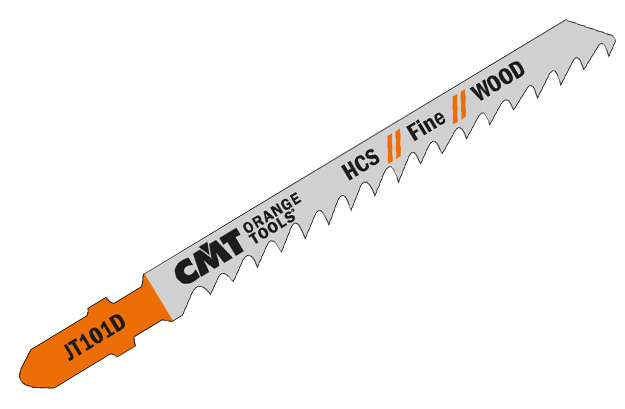

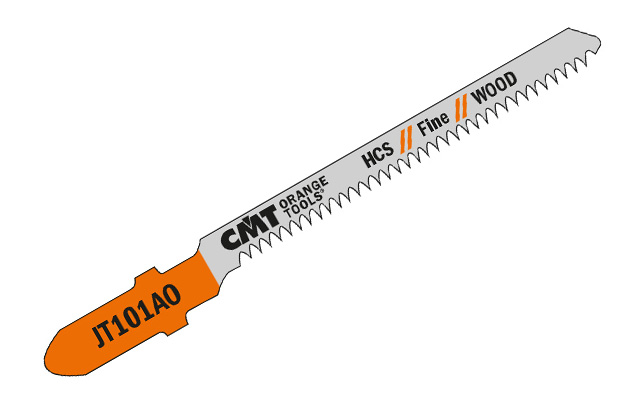

Jig saw blades

Apri filtri

Chiudi filtri

Jig saw blades

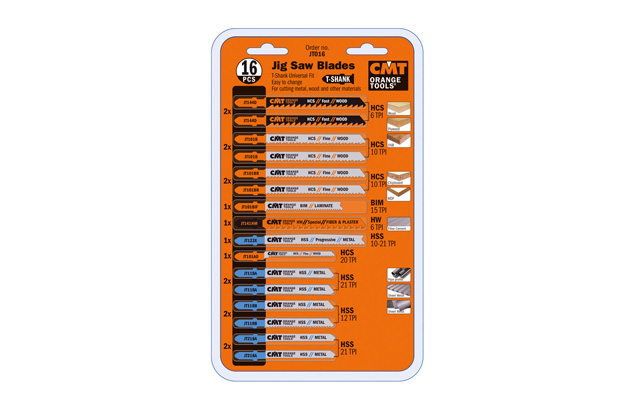

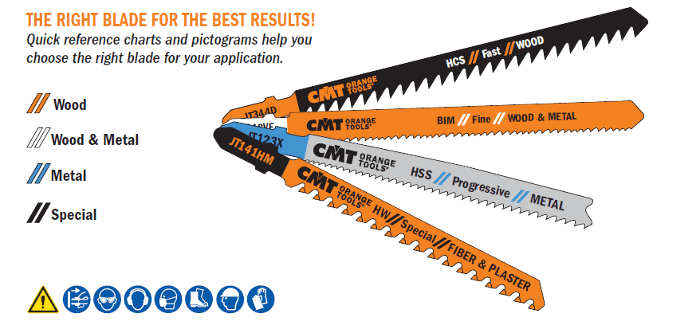

Produced by following state-of-the-art processes and by using high-tech machines, these jig saw blades have been specifically designed for precise cuts on soft & hardwood, plywood, OSB, laminates, plastics, HPL, multiplex panels, metals, ferrous & non-ferrous materials, aluminium, fiberglass and also stainless steel. These are made of four different materials.

HCS (high carbon steel). For use when cutting softwood, wood fiberboard and soft plastic.

BIM (bimetal). Suitable for use with hardwood, abrasive wood and harder materials such as ferrous and non-ferrous materials. The special bond of HCS and HSS addresses an array of cutting requirements. Thanks to its characteristic flexibilty, it is more resistant to shank breakage and lasts much longer. An excellent value for your money.

HSS (high speed steel). For use when cutting harder materials, such as metals, aluminium and non-ferrous metals.

HW (Tungsten Carbide Tipped). For use with fiber cement panel, plasterboard, MDF, GRP (fiberglass), and Elernit®.

Geometry is important.

Milled and side set teeth. Jig saw blades featuring this kind of geometry produce a quick rough cut into soft/hardwood, aluminium, plastic and non-ferrous metals.

Milled and wavy set teeth. Suitable for fine straight cuts into plywood, soft steel, aluminium, non-ferrous metals and plastic.

Ground and side set teeth. This geometric attribute creates fine, clean and precise cuts in wood and plastic.

Ground and taper ground teeth. This geometry delivers fine and clear cuts in wood and plastic.